FAQ's

The automotive battery provides starting power for the engine. It also supplies power to accessories such as lights, fans and radio when the engine is not running. Between low engine speeds and when accessory load is greater at higher running speeds, a battery makes up the difference by stabilising the alternator output. This stabilising effect also protects a vehicle’s electrical system by smoothing out sudden high voltages which can damage electrical components. Batteries produce their power through a chemical reaction which is released when a load such as a globe, starter motor or electric fan is connected to the battery. Electrical current is generated when two different metals are placed separately in a liquid capable of conducting electricity. When the metals are connected together above the liquid, electrical current flows through the connection. The different metals are referred to as electrodes. Pure lead is used for the negative electrode or plate and a lead dioxide paste is used for the positive electrode. When a positive and a negative electrode are combined, (but not touching), they are referred to as a cell. Two or more cells connected together are called a battery. The positive and negative plates are always separated by a separator to the plated, they do not make contact and self-discharge. The liquid solution is called an electrolyte which consists of a diluted solution of sulphuric acid. The battery becomes discharged (or flat) when no more current flows through the cell. The cell can be recharged by forcing electrical current back through the cell in the reverse direction. The chemical reaction that takes place during discharge converts both the positive electrode and the negative electrode to lead sulphate. Water is produced and dilutes the strength of the acid. During recharge, the electrodes are converted back to lead dioxide and lead. The water produced during discharge is consumed returning the lead to its original strength. In addition, some electrolysis of the water in the electrolyte occurs breaking it down into its component gases: hydrogen and oxygen.

We recommend against adding any additives as they may cause impurities and may be detrimental to your battery.

You should, however, add distilled water only to accessible battery types, which require regular topping up and be careful not to overfill.

Automotive lead-acid batteries are recyclable and should not be disposed of in a general waste bin. You can hand over your old batteries to us at our store and we will ensure they are recycled by an authorised ULAB (Used Lead Acid Battery) collector. We are a member of Australian Battery Recycling Initiative (ABRI) and we are committed to the responsible recovery of used lead-acid batteries and use these batteries and the recycled lead in the reproduction of new lead acid batteries.

What's inside the battery makes a difference. Batteries are built with plates made of lead, alloys and lead oxide. Throughout its life, plates are charged and discharged thousands of times. The quality of the materials, workmanship, and special design features in the manufacturing process can make a significant difference in a battery's performance. Calcium lead alloys, demineralised electrolyte, and durable separator materials are just a few of the internal components that distinguish the quality of batteries. Our batteries have special applications (automotive starting battery, motorcycle, deep cycle, dual purpose, marine battery and others) suitable for your needs.

A starting battery is designed to deliver several hundred amperes of power to the starter motor within a few seconds. The power comes off the surface of the plates inside the battery. A battery with more plate surface and less resistance will deliver more instant power. Alternatively, a deep cycle battery is called upon to deliver a long, slow discharge of fewer amperes, for several minutes or hours, in deep cycle applications like trolling motors, etc. Deep cycle batteries have thicker plates and are designed for discharge cycles.

It is not recommended to use starter batteries for deep cycle applications as it will reduce battery life or may cause sudden death of battery due to shorted cell. Likewise, a deep cycle battery is not suitable for starting as it will not give enough power for cranking an engine.

Sealed valve-regulated lead acid (VRLA) technology encompasses both gelled electrolyte and absorbed glass mat (AGM) batteries. AGMs are mostly used in special applications where spill-proof / leak-proof design is required.

Yes. Recharging a wet lead-acid battery produces hydrogen and oxygen gas. While spark retarding cover/vent caps help prevent external explosions, sparks occur when jump starting, connecting or disconnecting the charger or cables and igniting the gas. Inadequate ventilation, poor connections and batteries not properly maintained may trigger causes of explosion unless the battery is designed for closed boxes such as caravans.

Battery replacement may be necessary if you experience any of the following: loss of power in cold or extended starts, slow or interrupted turnover of the starting motor, or if the battery discharge light on the vehicle instrument panel is lit. If you are experiencing any of these symptoms, you should have your battery and/or electrical system checked. Please contact us before you break down so you can avoid a major inconvenience.

Incorrect application, heat and vibration are the most harmful elements to a automotive or cycling battery. However, many other factors can cause failure, such as: corroded cables and terminals, lack of electrolyte maintenance, sulphating, alternator/regulator malfunction, and electric shorts.

When charging lead-acid batteries, the temperature should not exceed 45 degrees C. At this point it should be taken off charge and allowed to cool before resuming the charge process.

Cold Cranking Amps determine how much power you have to start your car in most climates. The basic job of a battery is to start an engine; it must crank, or rotate the crankshaft while at the same time maintaining sufficient voltage to activate the ignition system until the engine fires and maintains rotation. This requirement involves a high discharge rate in amperes for a short period of time. Since it is more difficult for a battery to deliver power and that the engine requires more power to turn over when it is cold, the Cold Cranking rating is defined in international test standards as: The number of amperes a lead-acid battery at -17.8 degrees C, can deliver for 30 seconds and maintain at least 1.2 volts per cell-volt battery. In other words, CCAIR-CONold cranking amps determine how much power you have to start your car on cold winter mornings. Cranking Amps (CA) or Marine Cranking Amps (MCA) are measures not recognised in Australia. The ABIA members (Aust Battery Industry Association on recognise Australian standard specifications in this case the CCA.

Reserve capacity is the time in minutes that a new, fully charged battery will deliver 25 amperes at 80 degrees F and maintain a terminal voltage equal to, or greater than, 1.75 volts per cell. This rating represents the time in minutes it will continue to operate essential accessories if the alternator or generator of a vehicle fails.

In other terms, it is a battery's ability to sustain a minimum vehicle electrical load in the event of a charging system failure. Under the worst conditions (winter driving at night), low beam head lamps, windshield wipers, and defroster while driving at low speeds.

Heat increases the rate of evaporation, which causes a loss of water from the electrolyte. Extreme heat also increases the rate of self-discharge and promotes the corrosion of the positive plate grids. Extreme cold dramatically reduces the speed at which chemical reaction can occur, while increasing electrolyte resistance. It is important to keep batteries at a full charge during periods of extreme cold. Those in a discharged state are susceptible to freezing, which can cause damage to the plates and container. Automobiles demand more from a battery in freezing temperatures as the motor oil thickens and makes the engine harder to crank. Heat is the number one killer of a battery. Although it increases the performance in the short-term, life is drastically reduced over time.

When a battery is discharged (flattened), the car’s alternator will try to recharge it as best it can. This added load on the engine may use more fuel than normal but in a minor way.

No. Using a car battery to run a fridge will reduce the life of the battery and it will eventually fail. If you are running a fridge, the best option to use is a ‘deep cycle’ battery. These are designed to produce a small amount of power over a long period of time. Usually rated in Amp Hours, deep cycle batteries are designed to be drained and then recharged. Ideally you should run with two batteries, main battery (automotive) for starting the car and an auxiliary battery (deep cycle) for the accessories.

Starting and other lead-acid batteries are perishable. As they discharge, soft lead sulphate crystals are formed in the pores and on the surfaces of the positive and negative plates inside the battery. When a battery is left discharged or under charged for a long time period, or the electrolyte level is below the top of the plates, some of the soft lead sulphate re-crystallises into hard lead sulphate (called “lead sulfation”) which unfortunately cannot be reconverted with recharging. This process is responsible for more than 80% of failures of deep cycle lead-acid batteries. The longer sulphation occurs, the larger and harder the crystals become, lessening a battery’s ability to be recharged.

Premature failures are generally related to one or more of the following causes:

• Overcharging or high heat under the car’s hood, resulting in loss of water (50% of cases), increased positive grid corrosion or plate-to-strap shorts.

• Sulfation resulting from loss of water, undercharging or extended periods of non-use

• Deep discharges or cycling of a standard starting battery

• Incorrect application/wrong size battery

• Excessive vibration caused by a loose hold down clamp

• Using tap water, as opposed to distilled water, leading to impurities

• Freezing due to a discharged battery

• Excessive kilometres and excessive starting such as taxi applications

• Small trips combined with irregular use of the vehicle can lead to undercharging and sulphation

As with most manufactured goods, a battery warranty covers the consumer against faulty materials and workmanship. A battery is unlikely to fail due to a Manufacturing fault past six months in service. To claim a warranty, proof of purchase is required. Once the battery has been declared defective (and if it is still within the specified warranty period) it will be replaced with an equivalent product at no cost. The warranty period for every battery will be indicated on the product as well as in the application manual. Be advised that your warranty will not be honoured if the battery has been subject to abuse, neglect (failure to maintain water levels or failure to use distilled water), a faulty charging system, overcharging or other indications of improper use. Installing a battery with lower capacity than originally specified by the manufacturer will likewise void your warranty. In most cases we can tell when the battery was made if there is any conjecture regarding the age of the battery.

A life cycle test is conducted in a laboratory under a controlled environment with discharge and re-charge cycles set at a certain rate. It does not reflect the different situations that the car battery is subjected to in real life situations. Warranty is the measure of the manufacturer’s belief on the service life of its batteries.

No. New vehicles with additional accessories and equipment are designed for a calcium battery. Moreover, its charging system’s higher voltage output compared to old vehicles is designed to charge lead-calcium batteries. Stop/Start vehicles and Hybrid Electric vehicles have different design parameters and their batteries are different to normal combustion engines. It is important to replace the genuine OEM (Original Equipment Manufacture) battery with a like for like technology product.

WHY CHOOSE A MORE EXPENSIVE BATTERY OVER A CHEAPER ONE?

Batteries are normally stocked in a three tier range – Good Better Best. Generally our batteries in the middle tier (BETTER) are based on OEM (Original equipment manufacturer) specifications. Each tier is varied by specification and warranty all of which determines life of the product. In essence you get what you pay for !

• What is Reserve Capacity?

Australian standard test which replicates alternator failure, stated time in minutes which a discharge current of 25 amps is applied until battery voltage falls below 10.5 volts. Reserve Capacity relates to the capacity of the battery and increases with the amount of active material in the battery.

• What is Cold Cranking? (CCA)

Australian standard test indicating the highest discharge current a battery can maintain at a low temperature of -18 C but maintaining a load voltage above 7.20 volts. Higher CCA can be achieved by increasing plate surface area, this relates to number and size of plates used in battery design. Temperature greatly influences a batteries ability to carry high currents and increases failure rate of worn batteries during winter periods.

• What is 20 Hour Capacity?

Similar to Reserve Capacity but discharge currents are much lower, equal to the C20 rating divided by 20. This rating is more useful for stand-by applications but is a good indication of capacity.

• Off Key Load

Installed batteries in modern vehicles have a small load which can drain enough capacity in a few weeks rendering the battery unable to crank the engine. Batteries should be isolated by removing the negative terminal clamp if vehicle is not used for long periods.

• Battery Acid

The correct concentration of Sulphuric acid is in the battery when manufactured, there is general no need to top up with acid in normal service life. Unit measure for concentration is Specific Gravity which is equal to density in grams per cubic centimetre, new batteries are mostly in the range 1.260 to 1.290 S.G

• Dry Charged Batteries

Not as common these days but some imported products are still available as dry charged and are supplied with an acid bottle. To make dry charged batteries, the plates are fully charged and dried before battery assembly, these can deteriorate if exposed to air so each cell must have air tight seals to store as dry charged. A dry battery is typically filled with 1.70S.G acid and given a short boast charge before it is ready for service.

Batteries must be subjected to regular testing to ensure their starting capacity is maintained at an optimum performance level. Visit our store today for a professional battery check. The battery must also be scrutinised for any physical condition which may reduce battery life and impede starting performance such as broken or damaged posts and leaks to the battery case or lid. It is always best to test the battery in the vehicle so we can test the operating conditions of the vehicle. Quite often the vehicle charging system leads to battery failure or poor performance but often it’s the battery that gets the blame.

The first step in evaluating starting capability involves testing a battery's state of charge using a hydrometer or voltmeter. All non-sealed batteries should be checked using a hydrometer. As a cheap and reliable method of determining state of charge, the hydrometer also reveals differences between cells and allows visual inspection of the electrolyte colour. Where the hydrometer reading shows no significant difference between cells and produces a reading of 1230 or above (at 20-25°C) the battery has sufficient charge for a load test. Sealed batteries must produce a voltage of 12.5 or greater before a load test may be performed. Since the loss/fail criteria varies depending on the make of load tester used, be sure to consult the instruction manual provided with the tester to ensure success.

Battery installation should only be undertaken by a professional installer and appropriate safety clothing must be worn at all times, including safety glasses. Here is a step by step guide to installation :

• Ensure appropriate safety glasses and clothing are worn at all times before installing or removing your battery

• Always refer to Vehicles Operating Manual before removing or installing a battery

• Check bonnet clearance before installing battery (ensure the new battery height is no higher than the old battery)

• To avoid loss of radio PIN codes and key vehicle data, connect a Memory Minder & remove keys from the ignition or out of Key fob range

• Locate the positive terminal and mark polarity on the cable.

• Remove the negative cable first.

• Remove the positive terminal. Remove battery hold down.

• Inspect the tray for corrosion. If necessary, dust off corrosive residue.

• Place the new battery in the tray and ensure the battery is level and the terminal posts are in the same position as the old battery.

• Replace the hold down clamp and ensure battery is secure.

• Replace the positive terminal lead and tighten.

• Replace the negative terminal lead and tighten. (The negative terminal should always be replaced last)

• Never tighten or hammer terminal onto the battery as this can damage the posts and battery cover and will void the warranty.

Before charging begins, read the instructions of the battery label and the vehicle handbook instructions. These should be followed. Provide plenty of ventilation and ensure safety glasses or face shield are worn. Sparks from loose connections or metal tools making contact between the terminals or the undergrounded terminal and nearby grounded metal parts can also be hazardous. Do not remove the vent caps (maintainable product only) and do not charge the battery unless you are thoroughly familiar with the step-by-step procedure of recharging a battery. Ensure you have read the manufacturers instructions for the specific charger you are using prior to commencing the charging procedure. Here is a general step by step guideline :

• For maintainable battery types only - loosen the vent caps and then place a damp cloth over the vent caps, prior to commencing. For maintenance free product, continue to step 2.

• Connect the charger leads to the battery terminals, red positive (+) lead to positive terminal and black negative (-) lead to the negative terminal. Rock the charger lead clamps to make certain a good connection has been made. Set the electric timer to the desired charge time

• Turn on the charger and slowly increase the charging rate until the desired ampere value is reached. Do not charge in the red zone. If the battery starts to emit smoke or dense vapour, shut off the charger and reject the battery. If violent gassing or spewing of electrolyte occurs, reduce or temporarily halt the charging. (contact us further assistance)

• Never touch the charger leads when the charger is ON. This could break a connection at the battery terminal and create a spark which could ignite the explosive gases in the battery. Never break a 'live' circuit at the battery terminal for the same reason. Always turn the charger OFF before removing a charger lead from the battery.

The following charging rates and times assume a fully discharged condition.

RESERVE CAPACITY (RC) Expressed in minuted and found on battery type label SLOW CHARGE

Up to 75 mins 15 hrs @ 3 amps

75 mins to 130 mins 21 hrs @ 4 amps

130 mins to 180 mins 22 hrs @ 5 amps

180 mins to 250 mins 23 hrs @ 6 amps

Above 250 mins 24 hrs @ 10 amps

Many chargers available will automatically adjust to discharged condition and commence ith a boost charge gradually changing to suit the battery condition and then switching off at the fully charged rate. If not an automatic switch mode charger use the above as a guide.

• Visually inspect battery terminals, clean or replace as necessary.

• Check hold down clamp and replace if necessary. (Battery must be secured to avoid unnecessary vibration).

• Remove battery vent caps if fitted and check battery fluid level which should be 12mm above plates. Top up using deionised water. For Sealed maintenance free batteries, don’t remove the vents.

• Check vehicle for current drain using Electronic Tester.

• Check vehicle charging system. For 12 volt vehicles, reading should be between 13.8 volts and 14.6 volts.

• As a final check, check terminals, earth lead, and hold down clamp for tightness.

A common problem found with batteries is damaged caused due to undercharging, even new batteries can can start to suffer from sulfation from self-discharge. Batteries which have self-discharged over longer periods can only be recharged at low currents due to sulphated materials inability to chemically convert. Regular top up charge for batteries in storage is highly recommended. Vehicle electrical and charging systems are becoming more complex and we recommend fitting by professional installers only. For more Help and advice visit our store or call us.

- Charge Rates

- Excessive Vibration

- High Loads

- Electrical System Faults

- Faulty Terminals

- Stop/Start Motoring

- Sulphation

- Other

Australia has some of the harshest conditions in the world. Our extreme temperatures and varied landscape can seriously affect the life of a battery. Not all batteries are created equal. Our range of batteries have been designed to withstand the high under-bonnet temperatures and excessive vibration experienced by motorists; and our full product range of automotive, marine, deep cycle and industrial batteries, provides consumers with the best solution for every application. To help maximise the life of your battery, follow these helpful tips:

• Keep batteries topped up (maintainable batteries only)

Maintaining a sufficient electrolyte level ensures the electrolyte is neither too high or too low. Use distilled or deionised water and never over fill. Maintenance free batteries will usually not require topping up. Low maintenance batteries require the addition of water only once or twice per year depending on conditions.

• Check electrical connections

Make sure battery terminals and cable connections are clean and tight. The application of a thin layer of petroleum jelly can help reduce corrosion.

• Avoid overcharging and undercharging

Your vehicle’s charging system not working correctly can cause overcharging and/or undercharging of your battery. Overcharging can produce rapid deterioration and corrosion which shortens battery life. Undercharging can cause sulphation and premature design failure.

• Keep batteries clean and dry.

• Dirt on a battery's surface leads to discharge and corrosion. Avoid spilling oil or grease onto the top of the battery. To remove dirt or moisture, wash with a solution of bicarbonate of soda and water. Rinse afterwards with clean water. Ensure vent plugs are in place at all times.

• Precautions

To avoid shorting, metallic objects should not be placed on top of the battery. Batteries contain hydrogen gas and air in a volatile mixture which is easily ignited. Keep flames or sparks away from the battery at all times.

Batteries contain sulphuric acid. Never add acid to cells and keep acid away from eyes, skin, clothing or any other material which may become damaged. If contamination occurs, use large amounts of water to neutralise and flush acid away. Batteries are also heavy - ensure correct lifting procedures are used when moving batteries.

• Sulphation

An undercharged battery or underutilised battery will slowly discharge (go flat) over time and reduce its life. This is common in boats (over winter) or vehicles left unused for long periods of time. If you are not using any vehicle for a long period of time, disconnect the battery from the vehicle and recharge it before you reconnect it. You should ensure you have your Vehicle PIN number for resetting your electronics. Always keep a battery fully charged to ensure maximum life. You don't have to wait until you break down to change your battery. Avoid breakdowns by getting your battery tested on a regular basis. We can provide you with a battery check to determine the state of your vehicles battery system. Vehicle electrical systems are becoming more complex and its vital you purchase the right battery for your vehicle, so leave it to the experts.

Other factors that can cause premature failure of a battery include:

Batteries have a limited shelf life and when stored gradually lose their power to perform. On average, a fully-charged battery takes about 13 weeks to gradually discharge to less than its optimum operating level. The rate of charge loss depends on battery type (low maintenance or maintenance free) and temperature conditions. Charge loss becomes more evident when temperatures increase. At 20°C low maintenance batteries lose approximately one half of one per cent of charge per day (30 percent in 60 days). At 30°C charge loss is usually double the rate for 20°C. Under similar temperature conditions, maintenance free batteries lose their charge more slowly than low maintenance batteries. Excessive humidity will also accelerate charge loss. A battery stored upright in cool and dry conditions is ideal. Whilst in storage batteries that have not been recharged and allowed to go flat, may be permanently damaged. Recharging every four to eight weeks, depending on storage conditions, will restore batteries to "as new" condition. It is best to trust Exide Batteries and its National network of reputable stores to deliver the optimal product that is professionally managed.

• To avoid shorting, metallic objects should not be placed on top of the battery. Batteries contain hydrogen gas and air in a volatile mixture which is easily ignited.

• Keep flames or sparks away from the battery at all times.

• Batteries contain sulphuric acid. Never add acid to cells and keep acid away from eyes, skin, clothing or any other material which may become damaged.

• If contamination occurs, use large amounts of water to neutralise and flush acid away.

• Batteries are heavy ensure correct lifting procedures are used when moving batteries.

A Deep Cycle type battery is designed so that repeated cycling will not affect the battery's life or performance. Unlike the "SLI" battery which provides concentrated starting power, the deep cycle type battery supplies a constant but relatively low amount of current for a long period of time when an extended power supply is preferred. Exide provides a range of batteries that are considered hybrid where they provide characteristics across both starting and cycling applications.

It is easy to decide which deep cycle battery is required and how long it will operate your equipment before recharging is necessary.

First you need to establish:

• The Loading of each piece equipment. This is expressed in watts and is stamped into the compliance plate attached to the electrical item.

• The length of time (in hours) that it is intended to operate each piece of equipment between recharges.

• The system voltage (6v, 12v or 24v).

STEP 1 - The first step is to determine the total number of "Watt Hours" involved. Calculate this by multiplying the loading of each piece of equipment (watts) by the number of hours you intend to use it between recharges and then add them up. Follow this example of a boat owner who is operating a winch, fridge, communication equipment and uses the interior lights for extended periods

STEP 2 - The next step is to determine "Ampere Hour" (AH) requirement that the battery must accommodate. You calculate this by dividing the watt hours by the system voltage. Continuing the boat example:

500 Watt Hours divided by 12 volts (system voltage) = 42 Ampere Hours

STEP 3 - Battery cables are not perfect so it pays to make allowances for loss of power. A cable loss margins of 10% is usually appropriate. In addition, it's nice to have a little more capacity than you will need. Therefore, we recommend you build in an over-capacity margin of about 25%. Deep cycle batteries can be used for engine starting purpose; but only as a backup of the existing starting battery. If it is used, you will need to increase the Ampere Hour estimate by 50% to ensure you have starting power when the battery has been partly discharged.

STEP 4 - Having established the number of Ampere Hours required, refer to the Deep Cycle Battery Specification listing to choose the correct battery for your needs. There is one further consideration. Battery capacity varies according to speed of discharge. The faster the battery is discharged, the fewer Ampere Hours it will deliver before requiring a recharge. Therefore, EXIDE Deep Cycle batteries are capacity rated for three lengths of discharge time. You will need to determine the length of time your battery will be discharged over and match to the closest rated discharge time quoted.

If in doubt then please contact us.

Yes, an AGM battery is really a dual purpose battery. Our AGM batteries offers tremendous power ratings for engine starting in the most demanding conditions and also functions as a cycling battery for demanding applications such as 4WD dual battery systems, caravan/camping, sleeper cab support and trolling motors. As always, proper charging voltage guidelines must be followed.

Yes. Install a solid-state battery isolator to the vehicle's electrical system. This allows the trailer's batteries to be charged while driving and prevents discharge of your vehicle's starting battery. The isolator is becoming standard equipment on many motor homes.

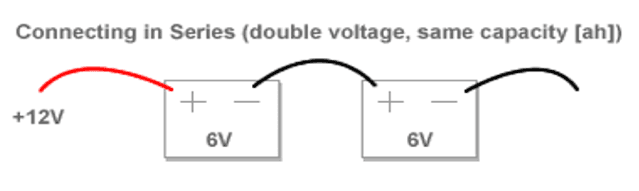

Yes. In order to use golf cart batteries for a 12-volt system you would need to connect the 2 batteries in series. Connect the positive post of the first battery to the negative post of the second battery. Then connect the positive lead from the equipment being powered to the first battery's positive post. Finally, connect the negative lead from the equipment being powered to the second battery's negative post.

Yes. Overcharging causes grid corrosion and reduces battery life. An automatic or timer switch charger are best.

No. But properly charging a deep cycle battery is a very important factor which can affect battery performance and life.

Batteries come in many different group sizes. A battery's group size simply determines it's length, width, height, and terminal configuration; this has nothing to do with a battery's capacity. Regardless of the group size, two batteries are equal in power if the CCA [Cold Cranking Amp] ratings are the same. New technology enables a great deal of power to be put into smaller cases with today's new high capacity output design.

The battery's state of charge can be tested using a hydrometer or a voltmeter. A hydrometer will determine the specific gravity of the electrolyte in each cell, while a voltmeter will give you a voltage reading. There are some batteries that come with a state-of-charge indicator eye built in the battery's cover.

First, you should check the motorcycle owner's manual for proper size and minimum recommended cranking amps. You can also consult a battery application guide by looking up correct make, model, year, and CCs to determine the proper size for your vehicle. Never use a battery with a lower capacity rating than is recommended by the manufacturer. Using a battery with a higher capacity is never detrimental, and is recommended for older vehicles to improve starting and provide longer life for the battery. The increased rating will not affect the starting and charging system.

Always follow the Vehicle handbook for instructions. Otherwise you can follow these guidelines. 1) Connect the positive [+] cable to positive post of discharged battery; 2) Connect other end of the same cable to same marked post (positive); 3) Connect second cable (negative -) to other post of booster battery; 4) Make the final connection on the engine block of the stalled vehicle away from the battery; 5) Stand back & start vehicle; 6 )Remove cables in reverse order.

A car charging system consists of three major components: 1. Alternator - the mechanical device driven by one of the engine belts. It produces a steady flow of electrical current on a continuing basis while the engine is running. 2. Voltage Regulator - monitors the state-of-charge in the battery to determine when and if more current should flow from the alternator into the battery to replace used electricity. When a battery is returned to full capacity, the regulator shuts off the flow of current from the alternator. This action occurs several times per minute. 3. Battery - an electrical reservoir used to store current until it is needed to power the engines starter motor. It provides sufficient electrical power, so the engine can reach starting RPMs. Once the engine is running, the electrical demand is supplied by the alternator alone to the coil, which continues to supply fire to the spark plugs. A simple analogy for a charging system is to compare it to a garden hose with a spray nozzle and a bucket/receptacle. Water flows through a garden hose as does the electrical current to the alternator. As long as the water/current is flowing, the hose/alternator is producing electrical current to charge the battery. The regulator, compared to the spray nozzle at the end of the hose, determines the amount of the electrical current released into the battery. The battery becomes the bucket/receptacle already filled with water. When water is removed from the bucket, the spray nozzle/regulator will open to allow water/electrical current to refill the bucket, or recharge the battery. Once the battery is completely recharged, the regulator will shut off the flow.

Extreme cold dramatically reduces the speed at which chemical reaction can occur, while increasing electrolyte resistance. It is important to keep batteries at a full charge during periods of extreme cold. Batteries in a discharged state are susceptible to freezing, which can cause damage to the plates and battery container. Automobiles demand more from a battery in freezing temperatures as the motor oil thickens and makes the engine harder to crank.

Heat is the number one killer of a battery. Although it increases the performance of the battery short-term, life is drastically reduced over time. Heat increases the rate of evaporation, which causes a loss of water from the electrolyte. Extreme heat also increases the rate of self-discharge and promotes the corrosion of the positive plate grids. Exide's patented AG-9 silver enriched grid alloy dramatically reduces corrosion and extends battery life twice as long as standard battery designs.

The life of a battery is determined by a number of factors, with the most important being the type of use of the vehicle coupled with proper maintenance. Amount of use, proper charging and climate are other elements that also need to be considered. A battery that is stored for prolonged periods of time or is in a vehicle with low usage patterns or recharging can develop sulphation on the plates which will greatly reduce the time a battery will perform. Conversely, a vehicle doing large amounts of work hours or kilometres will generally have a shorter life

There are a number of factors to consider when determining how often a battery needs to be replaced. These include vehicle type, region or climate, and driving habits. If your current battery performance is unsatisfactory, you may need to upgrade your battery to suit your particular situation and needs. Some vehicle manufacturers prompt replacement during a 3 to 4 year service which is deemed as preventative maintenance and in standard operating conditions, may prevent a sudden failure of the battery.

A sealed lead acid, AGM or VRLA battery have pressure valves or breather vents. They should have ventilation due to the chance of overcharging thus opening the pressure valves where gases can be expelled. This is a safety precaution that must be adhered to with all lead acid batteries.

Both batteries are sealed and are part of the VRLA family. Gel batteries typically excel in extreme deep cycling applications. Gel batteries do not do particularly well in temperatures less than 32°F due to increased impedance from the Gel and are not appropriate for high power applications. Gel batteries also have a low recharge voltage that prohibits their use unless special charging regimes are followed (typical alternator voltage is too high). AGM batteries have a lower internal resistance than Gel batteries allowing them to excel in high power and current applications. This lower resistance also gives the AGM battery a significant advantage in delivering its power in very cold temperatures.

A Gel battery is a VRLA battery that has an internal construction very similar to a traditional flooded lead acid battery. The difference is that a gelling agent is added to the electrolyte and pressure vents are added to the cover of the battery. Gel batteries can out gas early in life until the gel dries out and cracks form in the Gel to allow recombination. The gelled electrolyte can also flow which mean there are limitations in mounting orientations.

AGM stands for Absorbed Glass Mat. An AGM battery is a VRLA battery that has its entire amount of electrolyte "absorbed" in the separator material. The separator acts like a sponge and is saturated to approximately 98% (over 100% would mean free acid in the battery). This is why an AGM battery is spill-proof and can be mounted in virtually any position.

A cycle is simply discharging and recharging a battery once. Many companies advertise how many cycles a battery can achieve. One must be cautious when comparing these advertisements. How deep the battery was discharged, how the battery was recharged, what temperature the test was run and how a failure is defined all play into how many cycles a battery can withstand.

Yes, we stock batteries to suit all types of vehicles. If you have any special requirements, give us a call and we can get what you need in for you.

No, just drop in and we can sell and install your battery while you wait in the lounge.

If you purchase your battery from us, we will fit it for free provided it takes us the standard fitting time of 15 minutes.

If you are stuck in during business hours in the area, we may be able to come out and assist you. Conditions apply – please phone us for details.

The best way to safely dispose your battery is to hand it in to us for proper disposal and recycling. Do the right thing by the community and the environment and just drop it in for free and we will ensure correct handling is undertaken.

Connecting in Series: When connecting your batteries in Series you are doubling the voltage while maintaining the same capacity rating (amp hours). This might be used in a scooter, Power Wheels kids vehicle, or other applications. Just use a jumper wire between the negative of the first battery and the positive of the second battery. Run your negative wire off of the open connector from the first battery and your positive off of the open connector on your second battery.

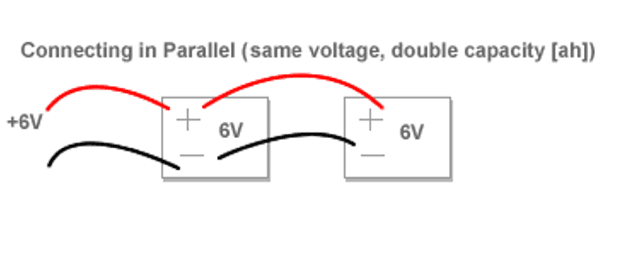

Connecting in Parallel: When connecting in Parallel you are doubling the capacity (amp hours) of the battery while maintaining the voltage of one of the individual batteries. This would be used in applications such as laptop batteries, some scooters, some ups backups, etc. Use a jumper wire between the positives of both batteries and another jumper wire between the negatives of both batteries. Connect your positive and negative wires to the same battery to run to your application.

Safety Tips

• Keep button batteries out of sight and reach of children. Remote controls, singing greeting cards, watches, hearing aids, thermometers, toys and electric keys may contain these batteries.

• Keep loose batteries locked away to prevent access by small children.

• Communicate the danger of swallowing button batteries with caregivers, friends, family members and baby sitters.

• If you suspect your child has ingested a battery, go to the hospital immediately. Wait for a medical assessment before allowing the child to eat and drink.

USEFUL VIDEOS

DOWNLOADS

PRODUCT INFORMATION

- RANGE SHEET

- FITMENT GUIDE

- PASSENGER VEHICLE RANGE

- START / STOP VEHICLE RANGE

- LIGHT COMMERCIAL RANGE

- HEAVY COMMERCIAL RANGE

- STOWAWAY MARINE BROCHURE

- CYCLING RANGE

- VRLA SMALL SEALED

- TECHNOLOGY

- TRADE CREDIT APPLICATION

PRODUCT SAFETY DATA & CERTIFICATES

HELPFUL ARTICLES

List of Services

-

Enerdrive ePower B-Tec Lithum BatteriesItem Link List Item 1

ePOWER B-TEC Lithium Battery Newcastle Batteries are very excited to announce that Enerdrive have released another great new high quality product. The all new ePOWER B-TEC lithium battery is in store...

-

Appliance and Load QuestionsItem Link List Item 2

Appliance and Load Questions: Do I need a pure sine wave inverter to run a television? In short, No. By using a modified sine wave inverter you will find that lines will appear across the..

-

MPPT v PWM Solar ControllersItem Link List Item 3

We have compiled a small amount of information that will hopefully help you to understand better what the difference is, and why you should choose an MPPT or a PWM type Solar Controller for your...